Technical parameters:

• Proxima Double Level Dry End Capacity: Able to handle 600 dry end order changes with production over 350000m2

• in a 12 hours production

• Single Level Dry End Order Change Speed: 300m/min

• Double Level Dry End Order Change Speed: 260m/min

• Liquid cooling servo motors with low inertia parts coupled with common dc bus and energy feedback system that

• enables to save more than 25% of electric power

• Self-developed state of art DCS control system with complete integration of electrical, electronic and mechanical

manufacturing that truly complies with Industrial 4.0

• Using EtherCat communication technique for logic, simple and high machinery functionality concept for complete line

Higher trim savings of 0.5%, 40% less paper width stock inventory and increase of productivity of 35% of a double

• level dry end system as compared to a single level dry end system

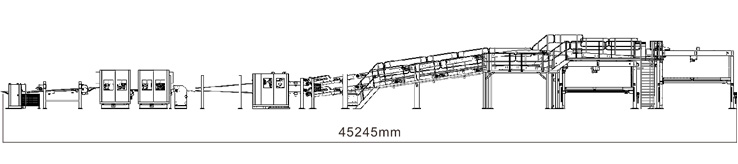

Single Level Dry-end:

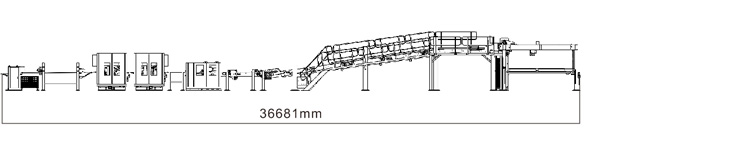

Double Level Dry-end: